Project B

Construction:

4 Weeks

Scope:

- Supply and Installation of racks and PDU

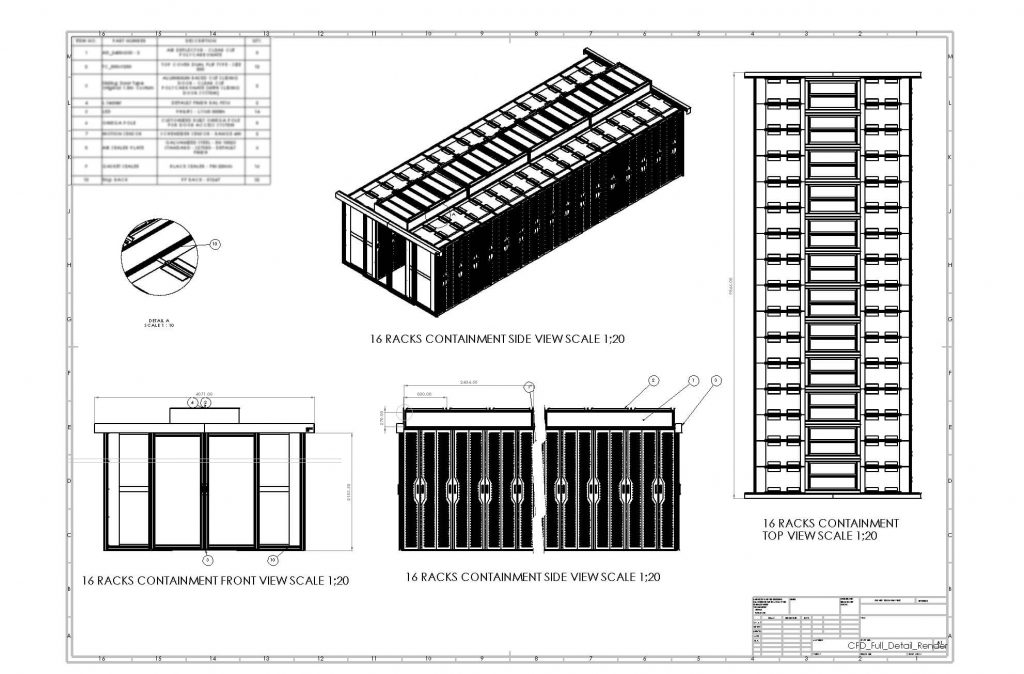

- CFD case study

- Design of Cold Aisle Containment

Intro

With the continuous increase in IT infrastructure demands, data centers are becoming more power-hungry and require more efficient cooling solutions. This project highlights how the design and installation of cold aisle containment systems can significantly enhance the cooling efficiency and performance of a modern data center. The project also included the installation of over 200 Power Distribution Units (PDUs) and the setup of 80 server racks. This complex initiative aimed to optimize airflow, reduce energy consumption, and improve the overall cooling efficiency of the data center.

Key Components of the Project

The project involved several key components and phases, each contributing to the ultimate goal of optimizing the airflow and cooling efficiency of the data center.

Cold Aisle Containment Design:

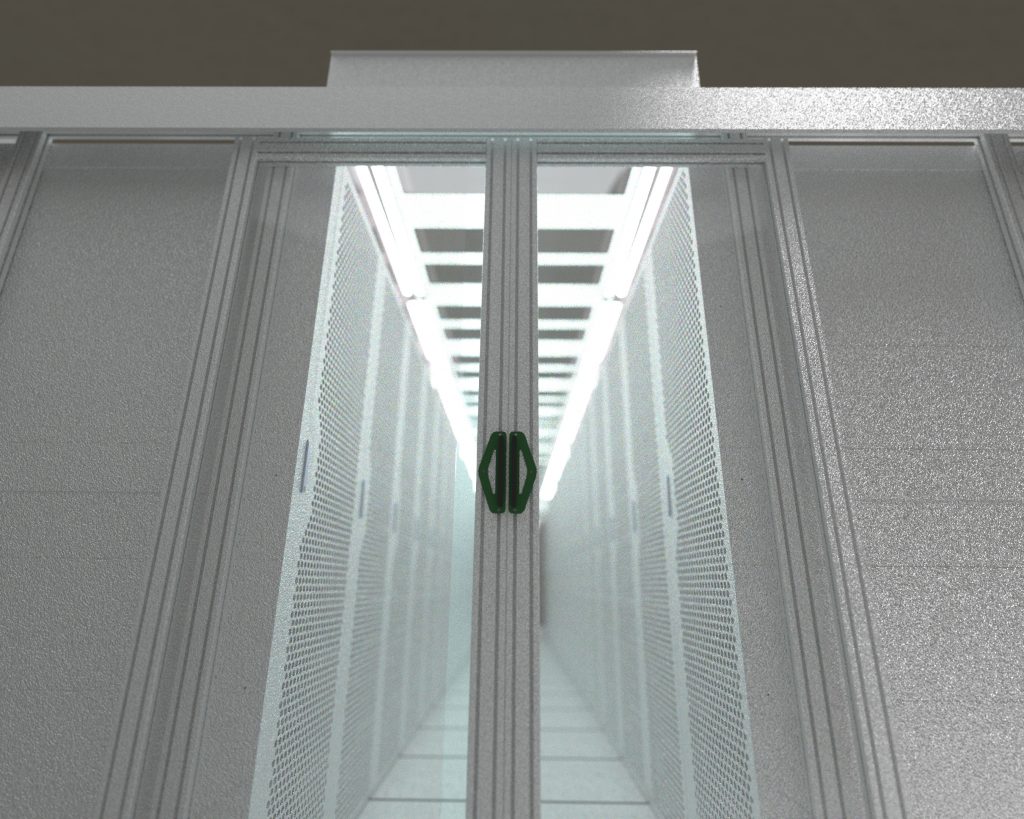

Our engineers designed a highly effective containment system to isolate the cold aisle from the hot aisle. This system included transparent partition walls and doors, allowing for easy monitoring and accessibility while ensuring the separation of airflows.

The design was tailored to fit seamlessly with the existing layout of the server racks and airflow requirements.

PDU Installation:

Over 200 PDUs (Power Distribution Units) were installed to ensure reliable power distribution to the server racks. These PDUs were strategically placed to maximize power delivery and ensure redundancy, ensuring the data center’s uptime and efficiency.

Installation of Cold Aisle Containment:

Over the course of several weeks, the cold aisle containment system was installed in the data center. This process involved the careful positioning of containment walls, ceiling panels, and airflow management components.

Specialized mounting and support structures were used to ensure the integrity and stability of the containment system, even under the heavy load of server racks and PDUs.

Server Rack Installation:

A total of 80 server racks were deployed within the data center. These racks were carefully arranged to optimize the flow of cold and hot air, maximizing cooling efficiency.

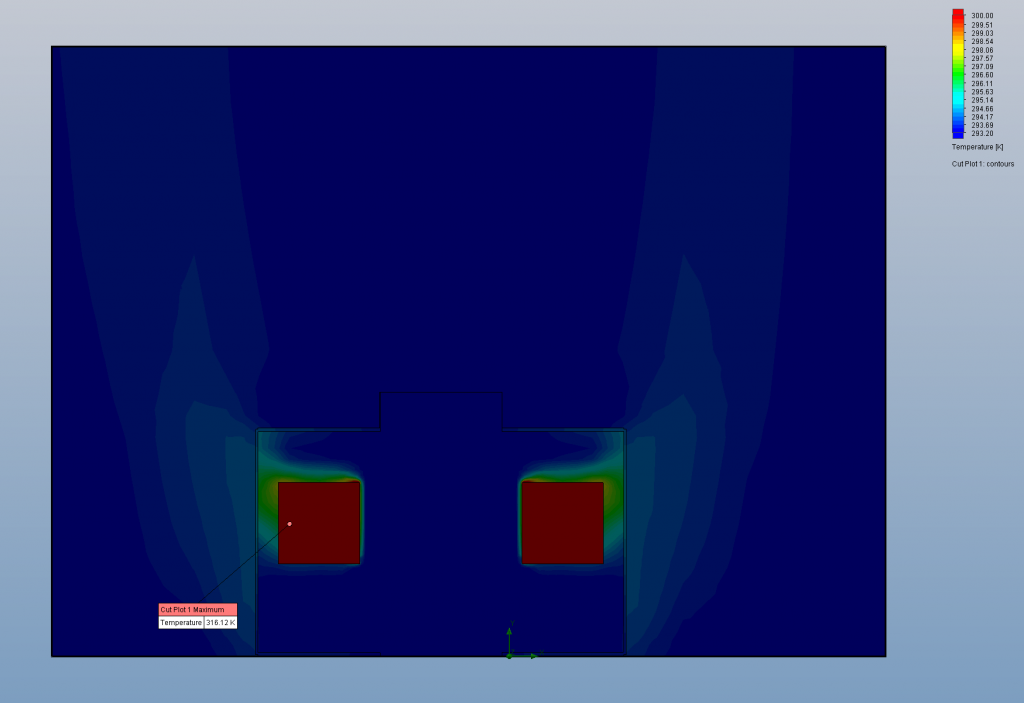

Importance of Cold Aisle Containment: CFD Analysis Results

One of the highlights of this project was the use of Computational Fluid Dynamics (CFD) analysis to validate the performance of the cold aisle containment system. CFD simulations were conducted to compare the temperature distribution within the server racks with and without containment. The results provided valuable insights into the significance of effective cold aisle containment for maintaining optimal server temperatures.

| Without Containment | With Cold Aisle Containment |

| In the traditional open-air design without any containment system, the cold air from the CRAC units (Computer Room Air Conditioning) easily mixes with the hot air exhausted from the servers. This results in inefficient cooling, as cold air does not reach the servers effectively. | The CFD analysis showed a significant reduction in server temperatures when cold aisle containment was implemented. With the containment system in place, cold air from the CRAC units was directed precisely into the cold aisle and delivered directly to the front of the server racks. |

| Servers located at the rear of the rack may receive warm air that has already passed through other servers, leading to inconsistent cooling and higher operating temperatures. | The temperature drop within the servers was evident, with an average reduction of 4-6°C (7-11°F) across the entire rack, resulting in a more stable and controlled environment for the servers to operate. |

| Additionally, the system ensured that the warm air exhausted from the servers was contained and expelled efficiently, preventing it from mixing with the cold intake air. |

The CFD results clearly demonstrated that cold aisle containment significantly improves temperature control, which leads to increased energy efficiency and reduces the risk of overheating, extending the lifespan of the servers.

Energy Efficiency and Cost Savings

By improving the airflow efficiency, the cold aisle containment system minimized the workload of the cooling units, leading to reduced energy consumption. The cooling units no longer had to work as hard to maintain optimal temperatures across the data center, resulting in substantial energy savings over time.

- The reduction in energy usage directly translated into lower operational costs for the data center, providing a quick return on investment (ROI) for the client.

- The optimized cooling conditions also helped reduce the carbon footprint of the data center, making the system more sustainable in the long run.

Conclusion

The successful design and installation of the cold aisle containment system, along with the deployment of over 200 PDUs and 80 racks, was a milestone in improving the efficiency and performance of this data center. Through careful planning, CFD analysis, and expert installation, we were able to deliver a state-of-the-art solution that enhanced temperature control, increased energy efficiency, and provided long-term cost savings.

By leveraging the power of cold aisle containment, the data center is now able to operate more efficiently, with a significant reduction in server temperatures and an optimized cooling system. This project highlights the growing importance of advanced cooling techniques in managing modern data centers, ensuring they remain reliable, energy-efficient, and sustainable in an increasingly digital world.

Flexibility, modularity, functionality and design are key criteria when selecting a suitable enclosure.

Our pledge to service, which provides us with a cutting edge to guarantee customer satisfaction.

- Cooling Solution

- Top Packaged Type

- Rack Split Type

- Bottom Packaged Type

- RDHx DX Type

- RDHx CW Type

- Containments

- Cold Aisle Containment

- Hot Aisle Containment

- Cage

- Security Cage

- Server Rack

- PF Series

- SCCR Series

- SWP Series

- SE Series

- SSR Series

- GSE Series